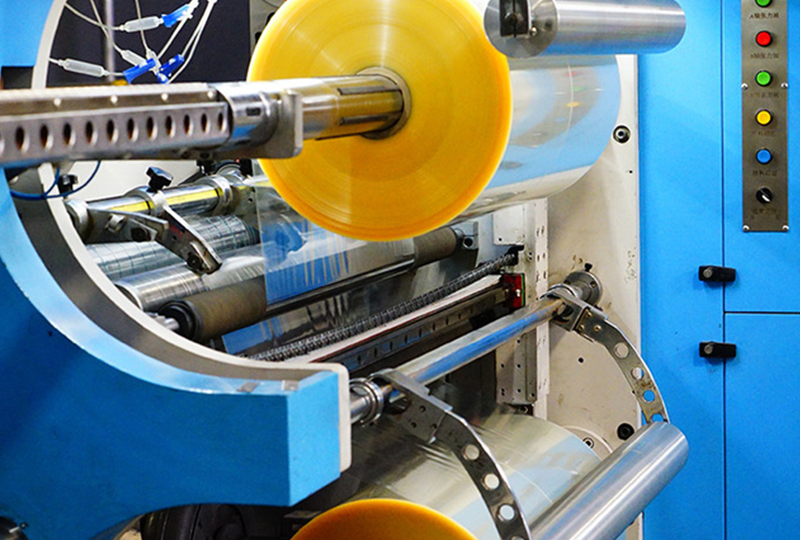

The trademark of heat shrinkable film is an emerging trademark. With the impact of imported beverages, a wave of shrink film used for trademark decoration is rising in China. The advantage of the heat shrinkable film trademark is that it tightly adheres to the bottle body after heating and contraction, preventing moisture from entering, preventing the pattern from being damaged, without wrinkles or bumps, and can be tightly adhered according to the shape of the object, making people feel novel and generous, plump and elegant.

Formulation Design of Multilayer Cooking Shrinkage Film

1. Inner layer

The first layer is a heat sealing layer, which can be achieved by using conventional heating methods. The fusion interface must have sufficient thermal stability to prevent gas or liquid leakage when processing food sealed in the bag at temperatures above or below ambient temperature. To adapt to the application of boiling in the bag, the heat sealing seal should be able to be immersed for a long time in humid air or steam environments or in hot water, Withstand elevated temperatures (71-72 ℃ or higher), while the fusion interface is able to withstand the tensile force of the food relatively sealed in the bag under disinfection temperature conditions.

Therefore, the first layer should use propylene ethylene random copolymer, with a propylene content of more than 90% and a melting point between 129-136 ℃. In addition, the meat adhesion properties of the inner layer of the film can be controlled through surface energy, including whether to perform surface treatment and the degree of treatment, such as through corona discharge treatment. Thin films with high adhesion to meat can reduce the loss of gravy during cooking in water. If they do not prevent the loss of gravy, they may result in loss of product weight. In addition, for applications that require retaining processing/packaging films for sale or use after processing, the loss of gravy during sterilization in water can make the appearance of the product unsatisfactory. Thin films with low adhesion to meat can be peeled off from the food immediately after being boiled and sterilized, and the food is further processed or packaged.

2. Adhesive layer

The second layer and the fourth layer are respectively prepared on both sides of the central layer to provide good interlayer bonding for multi-layer structures. They can also achieve a shrinkage rate of over 30% at low temperatures (not higher than 90 ℃) through directional stretching, while having good optical properties. These two layers typically contain three copolymers.

The first copolymer is linear polyethylene (VLDPE) with a very low density, typically between 0.900 and 0.915/cm3. This VLDPE has high shrinkage, high tensile strength, and stronger breakdown resistance. The second copolymer is EVA. The third copolymer is an adhesive resin of an anhydride grafted copolymer.

3. Central layer

The center used to be composed of EVOH, which controls the oxygen permeability of the film. In order to package perishable food, it is desired to minimize the oxygen permeability. Under a condition of atmospheric pressure, 23 ℃, and relative humidity of 0%, the oxygen permeability of the film is typically less than 10 cm3/㎡ within 24 hours. EVOH has a vinyl content of 38 mol% and a melting point of approximately 175 ℃. As the vinyl content increases, the melting point decreases and oxygen permeability increases. Although the central layer is essentially composed of EVOH, it can also contain 0-20% of the tool PA666 in order to change the properties of the central layer, such as gas permeability or moisture resistance.

4. Outer layer

The outer layer should be resistant to friction, mechanical damage, and stress caused by processing. It should also be easy for mechanical operations, including suitable for transportation, packaging, printing, bag making, and other processes. In situations where low temperatures (such as not higher than 90 ℃) and high shrinkage are required, it should also be easy for directional stretching, with good gloss. The outer layer contains two copolymers. The first type of copolymer is a very low density ethylene copolymer, VLDPE, with a density between 0.900-0.915/cm3 and a melt index below 1g/10min. It can provide a water vapor barrier layer to prevent moisture penetration, and good moisture barrier performance can prevent weight loss and drying of packaged food products. The second copolymer is EVA.

当前位置:

当前位置:

热门推荐

热门推荐

联系人:庞经理

联系人:庞经理