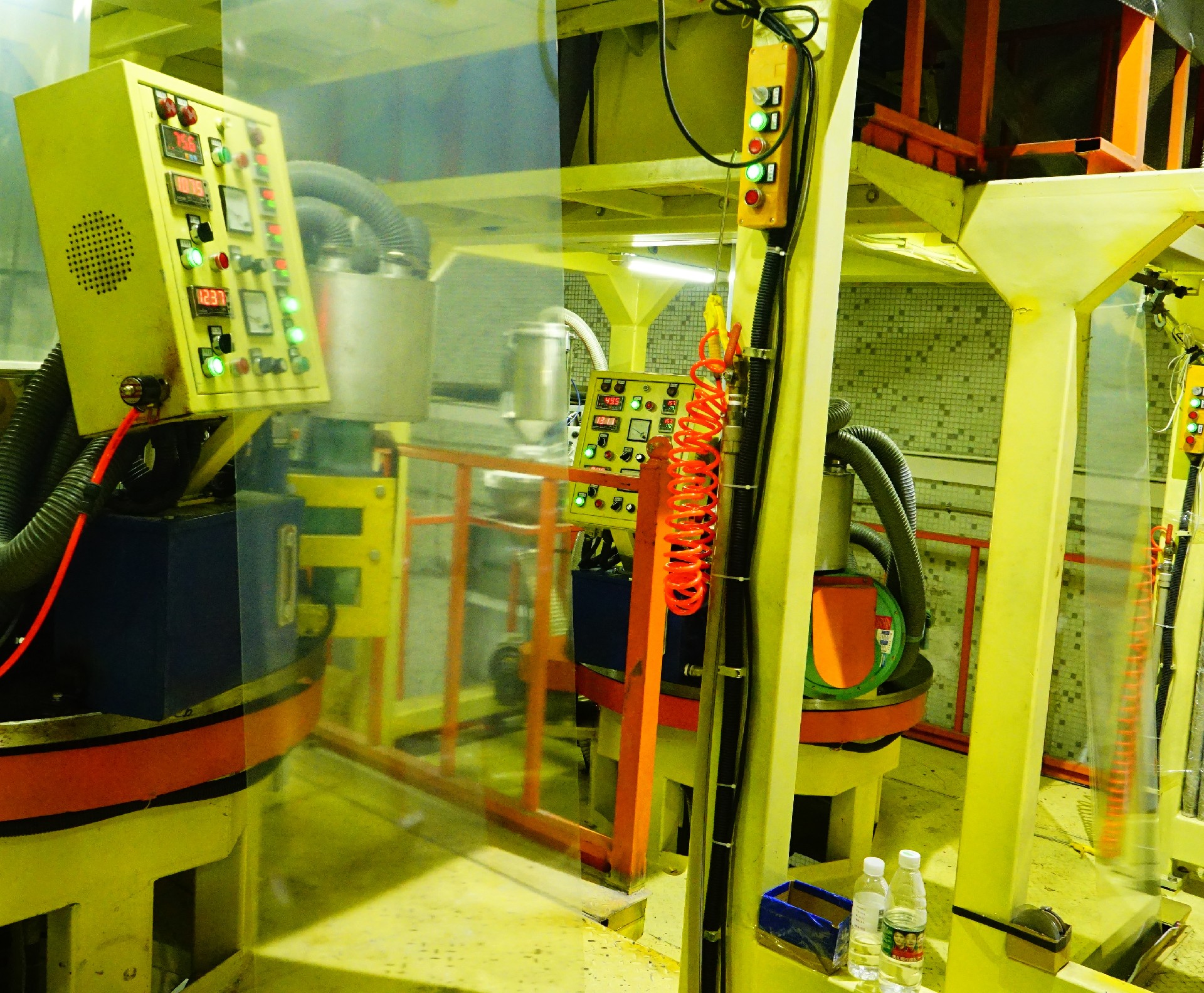

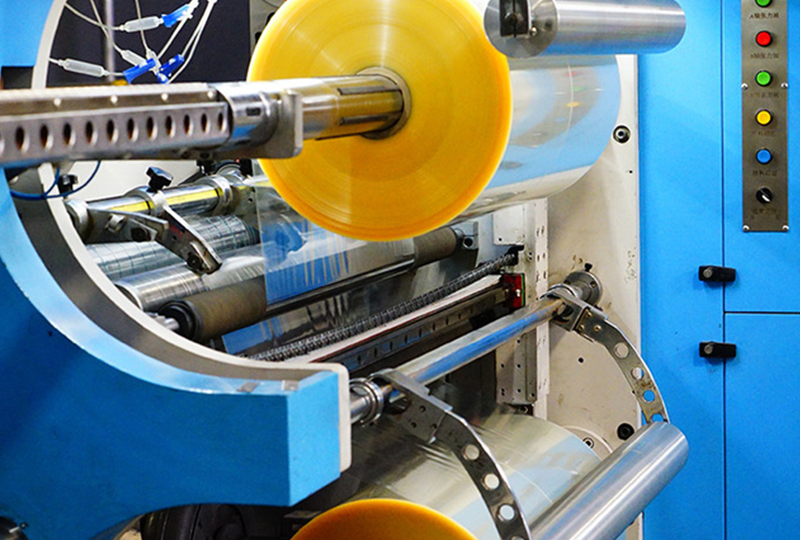

The stronger the light intensity, the more short-wave radiation, and the more long-wave radiation generated on the ground. The higher the temperature inside the heat shrinkable film, the greater the temperature difference inside and outside the heat shrinkable film. Therefore, in sunny days, with strong sunlight and high temperature inside the heat shrinkable film, it is often necessary to remove the heat shrinkable film and ventilate for cooling in production practice. The higher the temperature outside the heat shrinkable film, the less heat conduction loss of the heat shrinkable heat shrinkable film produced by Dongguang Hengxing Plastic Co., Ltd; The lower the temperature outside the heat shrinkable film, the greater the conduction loss. Therefore, there is a positive correlation between the temperature inside the heat shrinkable film and the overflow degree of the heat shrinkable film. Corona treatment is commonly used to improve the surface tension of thin films. However, there are some problems with corona treatment such as aging, especially in high temperature and humidity environments, where the film tension after corona treatment is easily attenuated. However, chemical coating laws do not have such a problem, so they are favored by the printing industry and the aluminum plating industry.

The main function of PVC heat shrinkable film is to stabilize, cover, and protect the product. The shrink film must have high puncture resistance, good shrinkage, and a certain shrinkage stress. During the shrinkage process, the film cannot create holes. Because shrink films are often suitable for outdoor use, UV anti UV agents need to be added.

Heat shrinkable film is widely used for the entire package of alcohol, cans, mineral water, various beverages, cloth, and other products. The product has good flexibility, impact resistance, strong tear resistance, and is not easily damaged, not afraid of moisture, and has a large shrinkage rate; The product is wrapped and packaged with the help of the retraction force of the wrapped film after stretching, forming a compact, spaceless unit that tightly wraps the pallets of the product together, effectively preventing mutual dislocation and movement of the product during transportation. At the same time, the adjustable stretching force can make the hard product stick tightly and compact the soft product, especially in the tobacco and textile industries, with a unique packaging effect. Shrinkage film has good abrasion resistance and high strength, ensuring that it can withstand the weight of the content. Printing belongs to printing inside the film (when pictures and text are inside the film sleeve), which can protect the imprint, and has better abrasion resistance of the label. Heat shrinkable packaging has good sealing, moisture proof, stain proof, and rust prevention effects, which can extend the storage period of food, facilitate storage, facilitate outdoor stacking, and save warehouse area. Heat shrinkable packaging process and equipment are relatively simple, and have good heat sealing performance, Adhesive is not required for labeling.

当前位置:

当前位置:

热门推荐

热门推荐

联系人:庞经理

联系人:庞经理