The annual usage of PE heat shrinkable film in Europe is over 400000 tons. The author has visited PLASTO, the third largest shrinkable film supplier in Europe, and its annual output in 2003 was 55000 tons, including 28000 tons of printed PE color shrinkable film, which exceeds the production of 27000 tons of unprinted PE shrinkable film (commonly known as white film or plain film in the industry). Its detailed composition is 28000 tons of printed color film, accounting for 51%; Others: 6100 tons are used for glass bottle packaging, accounting for 11%; 8600 tons are used for packaging paper, accounting for 15%; 8600 tons are used for milk packaging, accounting for 15%; 3700 tons are used for packaging of building materials such as bricks and tiles, accounting for 6%.

Environmental friendly PE heat shrinkable film, performance of shrinkable film and packaging application effect:

1. Beautiful appearance, which can make the film tightly adhere to the product, so shrink packaging is a kind of body-fitting packaging;

2. Can package various shapes of goods, and can shrink and package various shapes of goods in the same shrink bag, convenient for carrying;

3. Shrinkage packaging has good shock resistance, impact resistance, and good protective performance;

4. Shrinkage packaging has good cleanliness, can prevent dust and moisture;

5. The goods in the shrink packaging have good immobility, and the packaged goods will not be tilted in the middle of the packaging;

6. Good transparency, allowing customers to directly observe the integrity of the product

Main uses of heat shrinkable film: food packaging: fast food, dairy products, beverages, snacks, beer and various alcoholic beverages, agricultural and sideline products, dry food, local specialties, labeling and product sealing; Non food packaging: labels and closures, fiber and clothing, sporting goods, electrical products, pharmaceuticals, fats, detergents, stationery, toys, office supplies, kitchen appliances, daily necessities, groceries, building materials, and other packaging

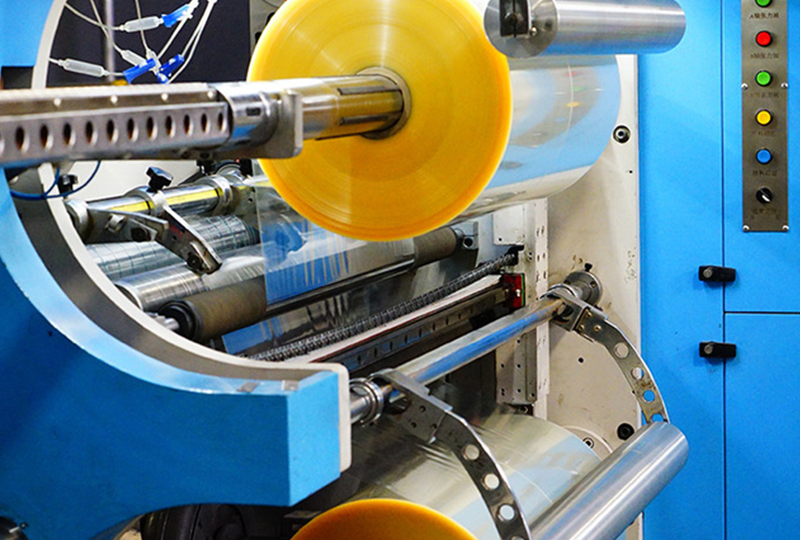

Effect of Heat Sealing Temperature on Heat Sealing Strength of Shrinkage Film

The heat sealing temperature directly affects the heat sealing strength of the heat shrinkable film. During packaging or bag making, if the heat sealing temperature is not properly set or adjusted, the following two situations may occur

When the heat sealing temperature is too high, exceeding the heat shrinking temperature of the heat shrinking film surface material, it can cause the film body to shrink and deform, resulting in adhesion between the shrink film and the heat sealing knife, and the heat sealing edge material is melted and extruded, resulting in undercutting

When the heat sealing temperature is too low, poor heat sealing may occur

当前位置:

当前位置:

热门推荐

热门推荐

联系人:庞经理

联系人:庞经理