悦龙薄膜南海·东莞

佛山市南海区悦龙薄膜有限公司

东莞市悦龙薄膜有限公司

- 悦龙首页HOME

- About UsABOUT

About Us

- ProductsPRODUCT

Products

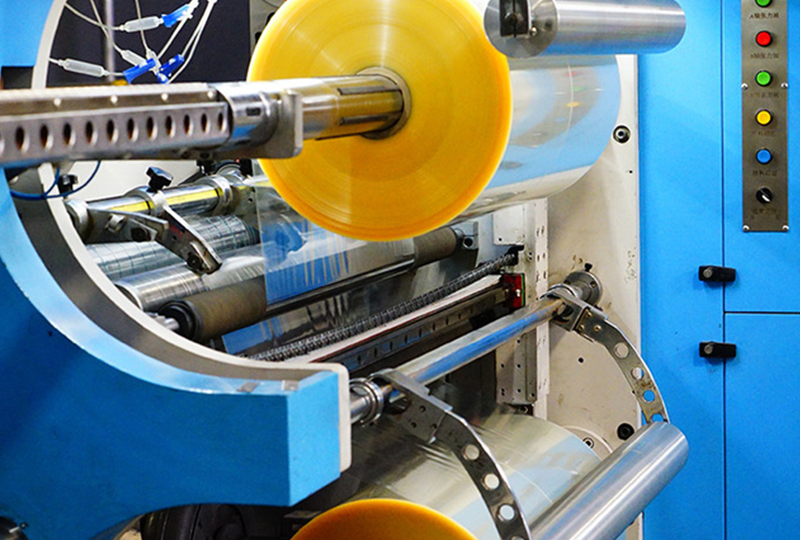

PVC heat shrinkable film is made by mixing PVC resin with a dozen kinds of auxiliary materials and then expanding it twice. It is ···【查看更多+】

- CaseCASE

Case

Widely used in the packaging of various commodities such as food, sports goods, disinfected tableware, electronic appliances, dail···【查看更多+】

- CertificateCERTIFICATE

Certificate

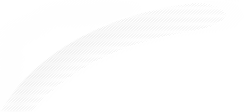

The company has established factories in Foshan and Dongguan, with balanced strength and wide market coverage. Today, our products···【查看更多+】

- NewsNEWS

News

Through the unremitting efforts of all employees of the company and the continuous adoption of new machinery and processes, the co···【查看更多+】

- Contact UsCONTACT

Contact Us

Foshan: Zone C, Science and Technology Industrial Park, Xingye Road, Shishan, South China Sea. Tel: 0757-86323208; Dongguan: No. 9···【查看更多+】

当前位置:

当前位置:

热门推荐

热门推荐

联系人:庞经理

联系人:庞经理