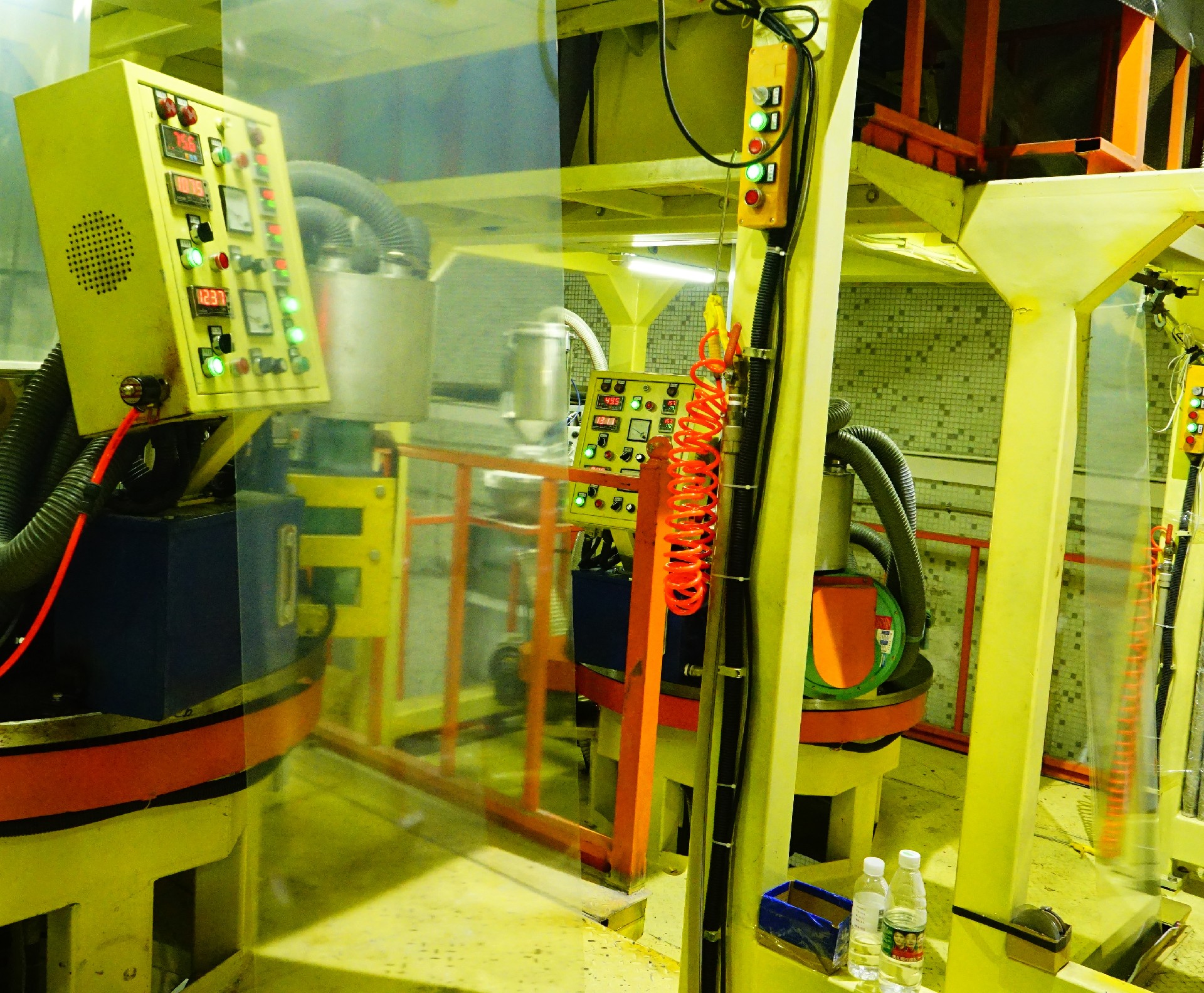

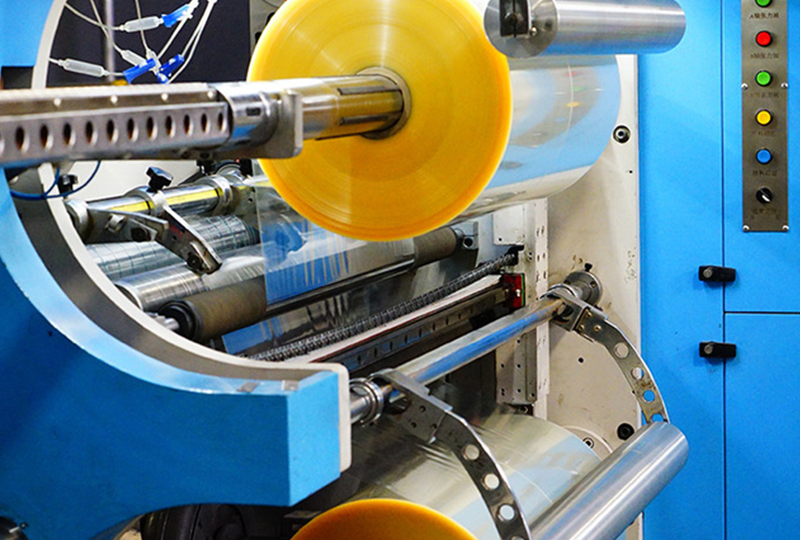

POF is mainly used for labeling, heat shrinkable packaging, or wrapping films. The main polymer resins suitable for preparing heat shrinkable films include PVC, PE, PS, PET, etc. After preheating, the film is stretched, cooled, and shaped (as long as it does not undergo heat setting treatment) to obtain a heat shrinkable film. At a temperature close to the resin Tf, the resin casting is stretched laterally and longitudinally, and then quenched to freeze the resin molecular chains in an oriented state, forming a heat shrinkable film. From raw material to the formation of a heat shrinkable film, there is a process of entropy reduction. The thermodynamic state of the heat shrinkable film is unstable. After the heat treatment of the shrinkable film, the aligned molecular chains quickly revert to a random cluster shape (curling state), causing the film to contract. Using this feature of heat shrinkable film, labels for special-shaped bottles can be prepared.

The parameters used to measure heat shrinkable films include shrinkage rate, shrinkage tension, and shrinkage temperature. Shenzhen Huale Plastic Products Co., Ltd. stated that considering the above three parameters, it is advisable to use polymer resins with low crystallinity or low crystallinity to obtain films with high shrinkage. Although the molecular chains of amorphous resins are oriented after biaxial orientation, no crystallization occurs. After receiving a second preheating, all the oriented chains can contract, and only the non crystalline oriented molecular chains will contract after being heated (lower processing temperature, shorter processing time); However, in order to achieve shrinkage of oriented crystalline molecular chains, the lattice needs to be destroyed, which requires raising the temperature to near the melting point, and the relaxation time of the molecular chain is longer, which is impossible to achieve during the use of the shrink film.

The higher the proportion of amorphous regions in a heat shrinkable film prepared from the same material, the greater the shrinkage rate and the greater the shrinkage force. The heat shrinkable film with a large amorphous region has a lower shrinkage temperature.

当前位置:

当前位置:

热门推荐

热门推荐

联系人:庞经理

联系人:庞经理